Performance characteristics:

The silicon core is a solid, permanent lubricant;

The silicon core layer of the inner wall is extruded synchronously into the high density polyethylene pipe wall, and evenly distributed throughout the inner wall of the pipe, will not flake off, off, and the same life as the silicon tube;

The silicon core layer on the inner wall has the same physical and mechanical properties as high density polyethylene.

The friction characteristics of the silicon core layer on the inner wall remain unchanged, and the cable can be drawn repeatedly in the pipeline.

The silicon core layer on its inner wall does not react with water, which can be used to flush the pipe after an accident.

Technical index:

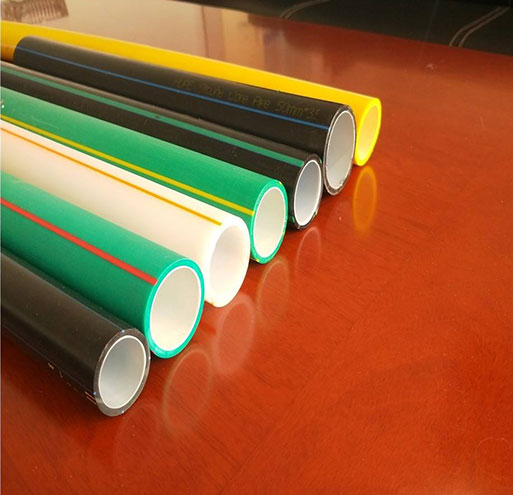

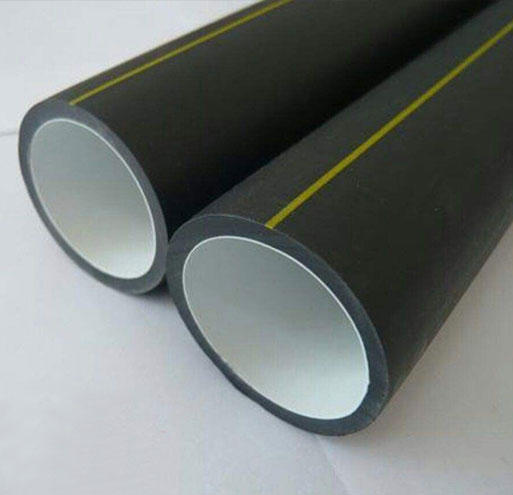

Appearance quality Appearance color uniformity; The inner and outer wall entities should be flat, uniform and smooth, without defects such as collapse, pits, holes, tear marks and impurities pitting; No bubbles and cracks in section; The inner wall is tightly fused without exculpation. The product identification on the outer wall is complete and clear.

Outer wall hardness ≥59 (Shaw D type)

Inner wall friction coefficient static: ≤0.25 (plate method, HDPE standard test bar)

Dynamic: ≤0.15

Cold bending radius (mm) 400

Ring stiffness (KN/m2) ≥50

When the flat test is pressed in the vertical direction until the outer diameter deformation is 50% of the original outer diameter, it is immediately unloaded, and the sample is not broken or stratified.

Recovery rate (%) When vertical pressure is applied to the outer diameter deformation of 50% of the original outer diameter, the sample is unloaded immediately, and the sample is not broken or stratified. The outer diameter can naturally recover to more than 85% of the original in 10 minutes.

Drop hammer impact resistance at room temperature 23℃, height 2m, with 15.3kg hammer impact 10 samples, there should be no cracking phenomenon in more than 9.

Low temperature -20℃, height 2m, with 15.3kg hammer impact 10 samples, more than 9 should not crack phenomenon.

Under the condition of temperature 20℃, pressure 50KPa, keep for 24 hours, no leakage.

Cracking strength (MPa) ≥2.0

Connection with pipe joint (N) ≥6700

Longitudinal shrinkage rate (%) ≤3.0

Melting temperature (℃) -75

Environmental stress cracking resistance 48h, failure number ≤20%

Melt flow rate (g/10min) MFR(190/2.16)≤0.5

Heat stress cracking 168h, failure number ≤20%

Power frequency breakdown strength (MV/m) ≥24

Corrosion resistance of chemical medium The tube samples were immersed in 5% NaCL, 40 H2SO4 and 40% NaOH solutions for 24h, and no obvious corrosion was observed.

After soaking in heptane for 72h, 528N external force is applied to the silicon core tube. The sample is not damaged, and the permanent deformation is less than 5%.