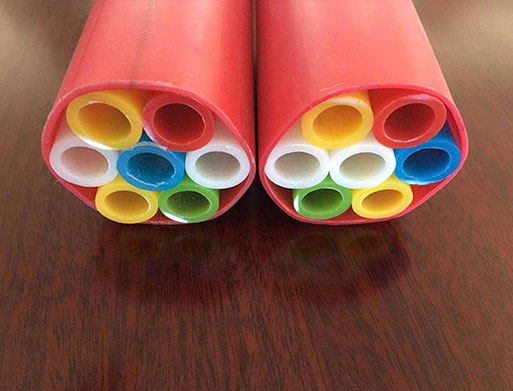

Advantages and disadvantages of cluster tube:

The advantage of bunched tubes is that the density of the tubes is high and the maximum number of microtubules can be accommodated in an effective space. The disadvantages are poor flexibility, inconvenient pipeline cutting (refers to the outer sheath with thick wall), difficult inner microtubule divergence, and poor impact resistance. Because microtubule units are tightly wrapped together by protective tubes, the deformation of protective tubes can directly cause microtubule deformation.

Cluster tube classification:

Cluster tubes are classified into three categories according to their application scope:

1. Straight mounted bunching pipe, often used in installed pipelines

2. Directly buried cluster pipe is often used for laying on both sides of the road

3. Overhead cluster pipe, often used in suburban overhead laying

At present, according to the purpose of the project, the cluster tube is divided into directly buried type, pipe type, binding type, flat type, overhead type, flame retardant type, termite-proof type and armored type. In terms of appearance, cluster tubes are round, polygon, square and flat. Circular tube is mostly thick-walled tube with outer sheath, polygonal tube is generally thin-walled tube with outer sheath, square and flat type of tube has thick wall and thin wall outer sheath.